Storing gases or vapours in high-pressure cylinders presents inherent risks, regardless of whether the cylinder is full or empty. The type of gas inside each cylinder influences the specific hazards, but even empty cylinders can pose significant dangers. In the UK, the Health and Safety Executive (HSE) sets the legal standards and guidance for the safe handling and storage of cylinders and drums.

One of the most immediate risks comes from gas leaks. These can occur during storage, transportation, or use and may be caused by faulty valves, cylinder damage, or human error. The hazards associated with gas leaks include:

- Flammable gas leaks – posing a risk of fires or explosions.

- Toxic gas leaks – endangering the health of staff and other personnel.

- Greenhouse gas leaks – potentially harming local plant life, wildlife, and contributing to ozone layer depletion.

Leaks may release gas slowly or rapidly, but both scenarios can lead to dangerous situations. The risks can be mitigated through proper cylinder handling, regular safety checks, and ensuring storage areas are well-ventilated.

At Storage N Stuff, we are industry leaders in providing safe and compliant gas bottle storage and handling solutions. Explore our range of products online, with free UK delivery, and feel free to contact us with any questions regarding safety or product selection.

Common Gas Cylinder Hazards

Gas cylinders are used in many environments, from industrial sites to domestic settings like BBQs. While gas leaks are the primary concern, other hazards associated with gas cylinders are particularly common in commercial and industrial spaces:

- Blast Impacts: If a gas cylinder catches fire, it can explode, creating a significant blast radius depending on its size. The explosion may hurl metal fragments at high speeds, leading to serious or even fatal injuries.

- Fire Risk: Fire is a major hazard when working with flammable gases such as liquefied petroleum gas (LPG). Fires can be triggered by leaks near heat sources, open flames, or other ignition points. Even non-flammable gases, like oxygen, can combust under high pressure.

- Falling Cylinders: Gas cylinders, especially those used in industrial settings, can be large and heavy. If a cylinder falls, it can cause serious injuries, especially to the head, feet, or body. Even smaller bottles, though compact, contain highly pressurised gas and can be equally hazardous if mishandled.

- Handling Accidents: Accidents during handling, such as mishaps with valves or pressure relief devices, can cause injuries. Poor training, low-quality handling equipment, or simple human error can lead to issues like crushed hands, toppling cylinders, and other potentially dangerous situations.

Despite these hazards, proper storage and handling practices can significantly reduce the risk. With the right precautions in place, handling gas cylinders should not be a dangerous task.

Safety Practices to Prevent Gas Cylinder Hazards

HSE has set up recommended safety practices for storing and handling gas cylinders, these include:

- Always store cylinders in an upright position

- Ensure cylinders are secured in a cage

- Keep cylinders well away from any heat sources

- Restrict all handling, storage, or use duties to trained personnel only

- Have fire extinguishers within easy reach while working with gas cylinders on-site

More best practices for avoiding gas cylinder handling accidents include:

- Wear appropriate PPE (such as gloves, masks, or eye protection) when filling cylinders

- Do not use a gas cylinder to fill up another one

- Ensure all handling areas (or storage areas) are sufficiently lit and ventilated

- Never drop, throw, or roll a gas bottle – even if it is empty

- Make sure all gas cylinders are secured and the valves are closed before transporting

Invest in Safe Gas Storage Solutions

With proper safety practices and storage solutions, you can handle gas cylinders safely and efficiently.

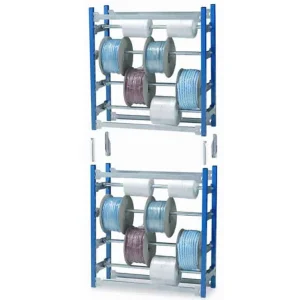

Check out our gas cages, cylinder wall racks and gas cylinder floor stands, which will make for excellent, convenient, and safe storage. We also have a wide selection of cylinder trucks, including 2, 3 and 4-wheeled trolleys, as well as gas cylinder transport pallets, which will help to reduce the risks of handling cylinders.

Prevent Gas Cylinder Hazards with Quality Storage

Gas cylinder hazards are varied and can potentially cause injury, or even be fatal in some cases. As a result, it is important never to compromise on safety standards in terms of best practices for storage and handling, or the quality of the products you use to carry out such duties.

We offer exceptional equipment for all sorts of industrial and commercial storage needs, including gas cylinders and other potentially hazardous items. You can browse our extensive range and buy online with free UK delivery and get in touch if you have a product question.