Rivet Racking Kanban

Rivet Racking Kanban, a cutting-edge system revolutionizing inventory management. With this innovative solution, businesses can streamline their operations, optimize space utilization, and enhance overall productivity.

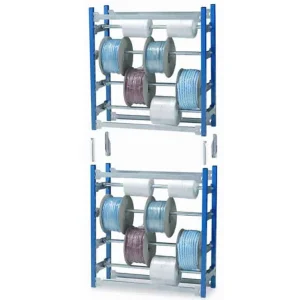

This Kanban system maximizes efficiency by employing visual cues, facilitating easy identification of stock levels. The system utilizes robust rivet racking, ensuring sturdy and reliable storage. This durable racking solution provides long-lasting support for organizing goods in a structured manner.

With the integration of the Kanban methodology, businesses can maintain optimal inventory levels by restocking items precisely when needed. This approach reduces the risk of stockouts or excess inventory.

Rivet Racking Kanban actively reduces the chances of human error in inventory management processes, guaranteeing accurate stock levels and avoiding costly delays or overstocking.

Results (3)

Our Best Sellers

More About Our Rivet Racking Kanban

One key benefit of Rivet Racking Kanban is its adaptability to various industries. Whether in retail, manufacturing, or warehousing, this system can be tailored to suit specific needs. Furthermore, it optimizes storage space, allowing businesses to make the most of their available area and enhance productivity.

With Rivet Racking Kanban, businesses can experience a streamlined workflow, reducing time spent on inventory management. Additionally, by providing clear visibility of stock levels, the system minimizes the risk of lost or misplaced items. This improves overall operational efficiency and empowers employees to focus on core tasks.

To summarize, Rivet Racking Kanban is a game-changer in inventory management. By combining the strength of rivet racking with the efficiency of the Kanban methodology, businesses can achieve optimal inventory control, streamline operations, and boost productivity. Implementing this innovative system brings order, precision, and cost-effectiveness to the forefront of inventory management.