We often overlook the marvel of mechanical handling systems technology that enables a seamless supply of the products we depend on in workplaces.

Mechanical handling systems encompass a range of equipment that orchestrates the storage and transportation of goods, playing a pivotal role in delivering an efficient and reliable distribution service.

Types of Mechanical Handling Equipment

There are four distinct types of mechanical handling equipment, and each serves a unique and integral purpose:

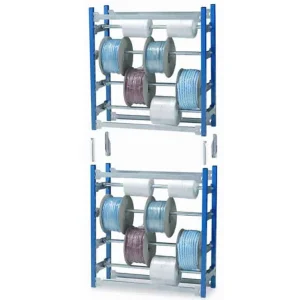

- Storage Equipment: Efficient storage is facilitated by an array of equipment, including racking units, shelves, bins, drawers, and drums. These components provide organised and accessible spaces for keeping goods.

- Bulk Handling Equipment: Bulk handling equipment is employed to handle large quantities of materials. This encompasses an assortment of machines such as rotary turntables, conveyor belts, elevators, stackers and other innovative mechanisms.

- Trucks and Movers: This type of mechanical handling equipment plays a crucial role in transporting and lifting items within industrial settings. Forklifts, order pickers, and hand trucks are among the machinery utilised to facilitate smooth movement and efficient operations.

- Engineered Systems: Engineered systems, which are often automated, consist of a whole host of components working in unison. A comprehensive setup might include a combination of racking and stackers, weigh scales, tumbler mixers, lifters, tippers and wash frames, harmonising various tasks seamlessly.

Industries That Rely on Mechanical Handling Systems

Several industries across the world utilise both small- and large-scale mechanical handling systems and equipment, but the two most common are:

Warehouses

Mechanical handling is the backbone of warehouse operations, optimising inventory management and order fulfilment in various commercial industries, especially retail.

Conveyor systems efficiently transport goods between different areas, while forklift trucks enable the swift movement of pallets and heavier loads. Such solutions expedite order processing, reduce labour costs, and improve overall warehouse productivity.

Construction

Building sites often require the handling of bulky materials and equipment during their day-to-day. Cranes and hoists enable safe lifting and precise placement of construction components, minimising the risk of accidents and expediting project timelines.

Additionally, storage solutions such as racking units, grit bins, and heavy-duty drums facilitate the organised storage of construction materials, enhancing accessibility and efficiency across the site.

The Benefits of Mechanical Handling Equipment

Enhance Worker Efficiency and Productivity

By implementing mechanical handling systems, you can optimise your workforce efficiency and productivity. Streamlined processes, automated tasks, and well-designed equipment enable employees to accomplish tasks with greater speed and accuracy.

Minimise Product Damage and Wastage

Mechanical handling solutions contribute to reducing product damage and wastage. Specially designed equipment, such as gentle conveyors or automated packaging systems, ensure the delicate handling of goods, mitigating the risk of spoilage or breakage.

Reduce Worker Accidents, Injuries, and Strains

One of the significant advantages of mechanical handling is the decreased likelihood of worker accidents and injuries. Ergonomically designed equipment, such as lift-assist devices or automated loaders, alleviate physical stress and promote a safer working environment for all.

Enhance Worker Satisfaction

By reducing physically demanding tasks and introducing efficient processes, employees experience improved job satisfaction and reduced fatigue, leading to a happier and more engaged workforce overall.

Streamline Workflow

The seamless integration of equipment, optimised material flow, and synchronised processes result in a more efficient and productive operational environment. Tasks can be completed with fewer bottlenecks and smoother coordination between different stages of production.

What to Consider When Buying Mechanical Handling Equipment

When selecting mechanical handling solutions for your business, it is crucial to consider several factors to ensure optimal performance and seamless integration. Here are some key considerations to keep in mind:

- Load Capacity: Assess the maximum weight and volume requirements of your materials or products, and then choose equipment with adequate load capacity to handle your specific needs without compromising safety or efficiency.

- Speed: Evaluate the desired speed and throughput of your operations in order to ensure that the chosen solutions can effectively handle the anticipated workload.

- Flexibility: Consider the flexibility of the mechanical handling solutions to accommodate changing requirements. Look for equipment that can be easily adjusted, reconfigured, or scaled up to adapt to evolving business needs.

- Integration Capabilities: Ensure seamless communication and data exchange between different equipment, such as conveyor systems, automated storage systems, or robotic components.

- Maintenance Requirements: Opt for solutions that offer reliability, ease of maintenance, and ready access to spare parts, to minimise downtime and ensure long-term operational efficiency.

- Compliance with Industry Standards: Your selected mechanical handling equipment should comply with all relevant industry standards, regulations, and safety requirements. This includes ergonomic standards, electrical safety, fire safety, and any industry-specific regulations applicable to your business.

Invest in High-Quality Mechanical Handling Equipment

Mechanical handling plays a crucial role in industrial settings, improving efficiency, reducing costs, and streamlining operations. Our expertise and range of industrial storage solutions, from shelving and conveyors to automated systems, are designed to optimise your processes and enhance productivity.

Discover how our cutting-edge solutions can transform your operations.